by Julie | Dec 20, 2020 | EOS, Innovation

Reflecting Back

As I stood outside my chicken coop this morning, I reflected back on all that has happened in 2020. When the pandemic hit, I had two goals in mind. First, to build a chicken coop and second, to give the gift of humanity to as many people as possible.

Focusing outside of myself has allowed me to impact many people and at the same time, I’ve been impacted by countless individuals. I appreciate all of you taking the time to read my blogs and provide tips on how to be a better chicken mama.

To end this year with some humor, I’m including some links to the most popular posts from 2020:

And, here’s the good news! I have 9 chickens in my coop including one rooster (who has already pecked me). 2021 promises to have more chicken business posts and maybe a few laughs.

Until then, enjoy the holidays and cheers to the end of 2020!

With respect and gratitude!

Julie

by Julie | Mar 5, 2020 | Innovation, Process Improvement

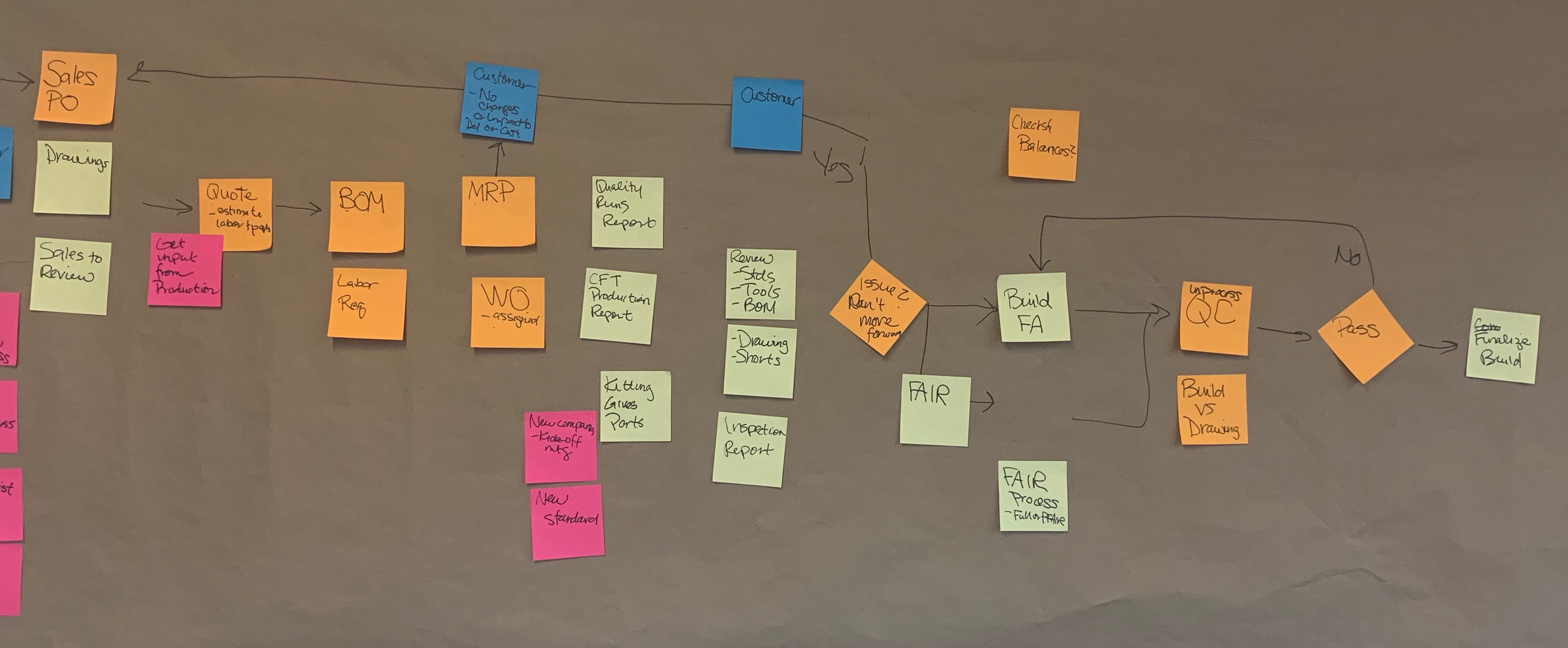

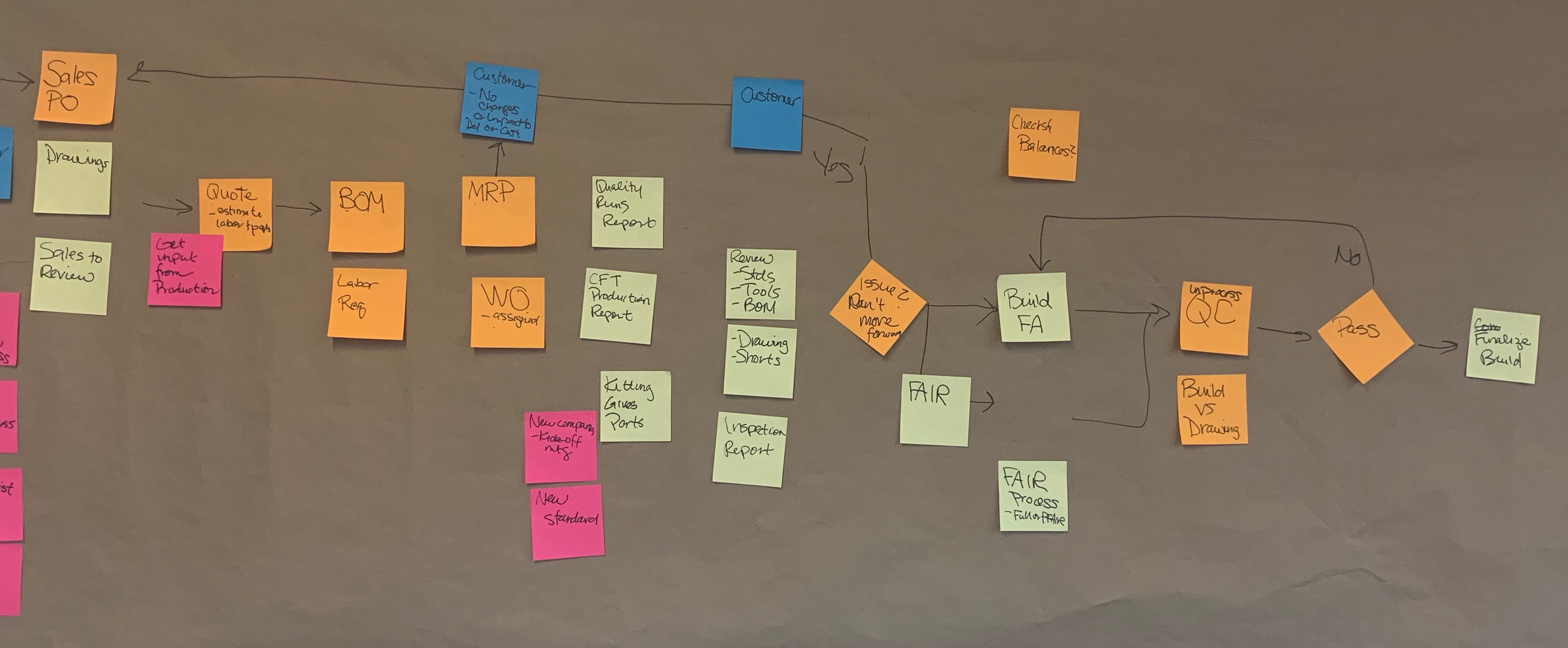

I was never a big fan of process flow maps. It seemed like such a tedious activity, which in my opinion didn’t do much but capture an already obvious process. But that all changed a few years ago. I was working with some Six Sigma Black Belts to develop a hands-on course on how to apply process control tools to the investment casting industry. We knew what we wanted to teach, we knew how we wanted to teach it, but we kept struggling with how to get where we wanted to go. After a few months of minimal progress, I mapped out the steps of the process we wanted the students to follow, identifying decisions that needed to be made and delays that could impact the flow.

What a game changer! This flow chart has become invaluable to students and to the instructors when we teach the class. Our instructors agree that mapping out the process was a turning point, and we often ask ourselves what took us so long to start using this tool, especially since it was a tool we were trying to teach the students to use.

A few weeks ago, I was mapping out a process for a client and we identified some delays that could be avoided if we added some steps earlier in the process. We also identified ways to increase customer satisfaction by adding a few minor steps at strategic points in the process.

Are you looking for ways to increase throughput without adding resources? Try process flow mapping. This can highlight gaps, opportunities for improvement and non-value-added steps. By addressing those, you can reduce delays, improve consistency and increase capacity. If you want help getting started, send me an email! I’d love to help you!

by Julie | Feb 27, 2020 | Innovation, Leadership, Sales

A business needs a product and sales.

A thriving business needs a product, sales, leadership, and innovation.

Here is how each of these contribute to the success of a business:

- The product is the cornerstone of the business.

- Sales provides cash flow to continue producing the product and to fund the business.

- Leadership sets the vision and focuses your resources in the right direction.

- Innovation creates new products, improves the way things are done, and helps implement the details behind the vision.

My consulting practice focuses on improving my clients’ profitability by focusing on these areas for any thriving business: Leadership, Innovation, and Sales.

Let me give you an example. A mid-sized manufacturing company was selling product in the highly competitive automotive industry. Their production line was struggling, resulting in $80,000 in scrap every month. This was crippling their company and damaging relationships with their key customers, because they couldn’t deliver their product on time.

I was able to quickly identify what was causing their scrap issues. Together, we put processes in place to address the gaps and strengthen existing systems. Once this was complete, I trained the engineers, supervisors, and operators on the new processes. Within six months, the cost of scrap fell to just $1,200 per month and throughput increased.

With additional capacity, stronger processes, and greater technical depth, the company was poised to pivot to a higher-margin, less-competitive industry. But in order to do that, they needed to develop a strategy for their sales and marketing team. Using my background in sales, understanding of the company’s plant capabilities, and the needs of the target industry, I led the sales team through the transition. Within a year, they had gained the recognition of the industry as a supplier who delivered on time with excellent quality. The company has been able to grow sales in their target market at a 20% increase year over year with a gross margin more than triple their automotive margin.

If your company wants to strengthen its internal processes in order to transition into a new market, I can lead you through the process, providing guidance and expertise along the way. Email me today to start on your journey tomorrow.